We provide the best products in the stainless steel industry. Our customers know they can trust us for quality, affordability, and convenience. Our multiple locations make it easy to get what you need within days!

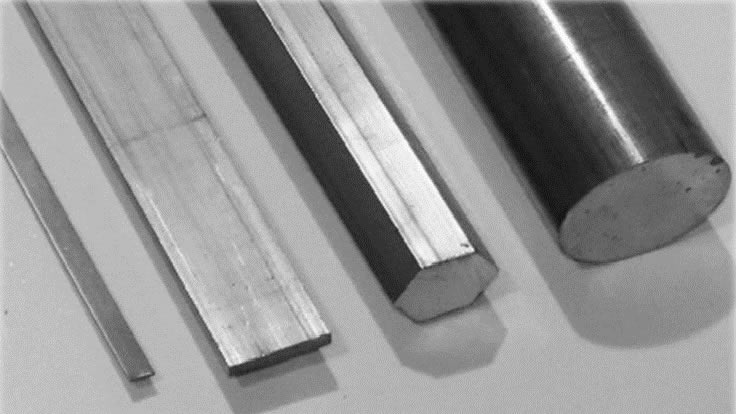

Cada Stainless is a distributor of stainless steel in strip, coil & sheet. All grades of stainless steel available- annealed, tempered in 301,302,304,316, straight and L grades, 17/4, 17/7, 420,430,440, temper rolling to specific thicknesses & tolerances available.

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

At Millennium Metals, LLC, we specialize in providing high-quality stainless steel products to meet the diverse needs of our customers across a wide range of industries. We take pride in offering an extensive inventory of stainless steel grades, shapes, and sizes, ensuring our clients have access to the materials they need, exactly when they need them.

At Alliant Metals, we dedicate ourselves to supplying high-quality stainless steel products and tailored services that meet the demands of a wide range of industries. As specialists in stainless steel, we work closely with our customers to deliver material that aligns with their exact specifications, whether the need is for standard stock or custom-cut solutions.

More Stainless Steel Coil Manufacturers

Stainless steel coils are highly sought-after because of their unique mechanical and physical characteristics. They are strong, lightweight, and corrosion-resistant. In addition, manufacturers can design stainless steel coils to meet custom design requirements. The market has different grades of stainless steel coils, each with special characteristics and applications.

Stainless steel coils are made by continuously hot-rolling stainless steel slabs. They are then wound tightly and left outside to cool down. This process ensures they finish with oxide- and impurity-free coatings.

Types of Stainless Steel Coils

Type 321

Type 321 steel coils are standard austenitic 18/8 chromium nickel alloy with titanium added. They are generally a great option for high-temperature situations. The titanium stabilizes the substance, increasing its resistance to intergranular corrosion. 321 is the preferred stainless-steel alloy choice when working in conditions up to 1652°F (900°C).

Type 347

Type 347 stainless steel coils are the best to use for welding. Therefore, the preferred consumable for welding grade 321 is type 347. Even at cryogenic temperatures, the steel is good for forming and welding.

Type 304

Suppliers commonly carry type 304L stainless steel coils. Coils made of stainless steel 304 have remarkable corrosion resistance. Stainless steel 304 coils are durable and don’t rust quickly. Coils of stainless steel 304 are less expensive than other materials in terms of life cycle costs. These coils are popular because they are long-lasting. This product has a high scrap value and may also be recycled.

Industries That use Stainless Steel Coils

In the automotive industry, stainless steel coils are used for applications that require strong corrosion resistance and lightweight materials. Stainless steel coils are often used in structural applications for automobiles. Additionally, the use of stainless-steel coils in busses, subways, high-speed railroads, and other transportation systems is spreading.

Stainless steel coils are often used in the desalination and construction industries. However, stainless steel coils were first used in the building industry. Stainless steel coils are frequently used in decorative panels on buildings' exterior and interior walls. They are not only incredibly gorgeous but also durable. In addition, they are used as decorating elements in the construction and automotive industries.

Stainless Steel Coils’ Benefits

By itself, stainless steel provides many benefits as a building material. To begin with, stainless steel is very durable. Additionally, this material can handle the pressure of enormous weight. Furthermore, stainless steel is known to be corrosion-resistant. It is also resistant to cold and heat. This resistance helps materials housed by stainless steel pipes or other stainless steel items maintain their temperature and, as a result, save money on energy costs. Furthermore, stainless steel is easy to recycle; however, based on the assets listed above, and others, a user should not expect the need to recycle an item made of stainless steel for an extremely long time.

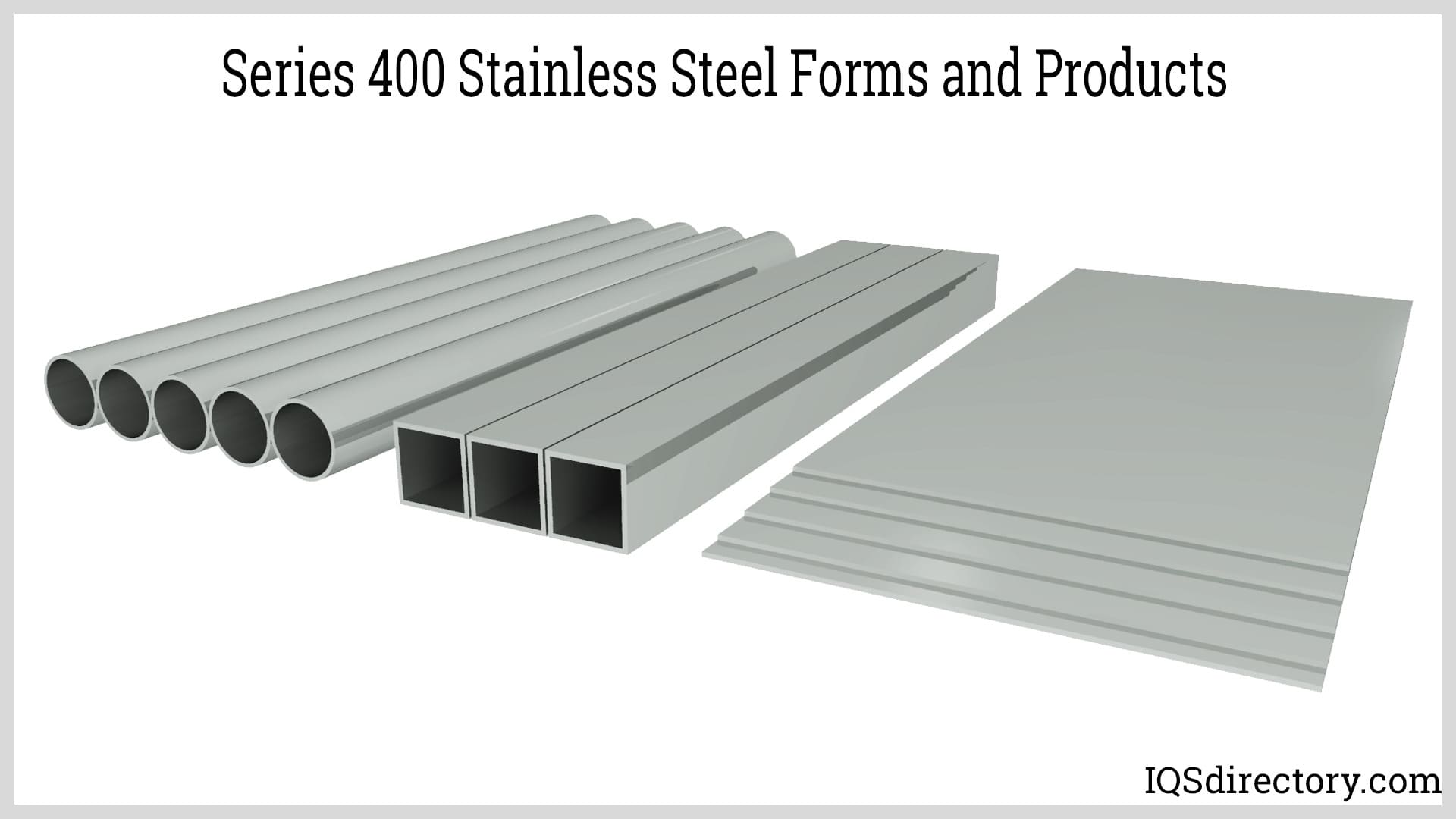

It’s precisely because of these benefits that stainless steel is formed into coils. As a coil form, this material is easy to shape into many products. Some items created from stainless steel coils include cutlery products, surgical instruments, filtration devices, various pipes and tubes, and various parts for air heaters, heat exchangers, and air coolers.

Conclusion

As hinted at, stainless steel coils have a wide range of mechanical capabilities and can be utilized to satisfy several requirements. Stainless steel is corrosion-resistant, lightweight yet incredibly strong, and needs little upkeep. As a coil form, stainless steel is primarily used in the industrial and construction sectors. However, they are also utilized in the mass production of nearly everything ranging from domestic items to industrial equipment. Stainless steel coils come in various varieties, each with a special function and set of characteristics. T300 series stainless steel 304 coils, for example, have a maximum of 0.08% carbon and a minimum of 18% chromium. It is categorized as chrome and austenitic nickel alloy. 304 stainless steel, sometimes known as “18/8,” is the most prevalent type of stainless steel used in pans and kitchenware.

Steel slabs are hot rolled in conjunction with a reheat furnace to create stainless steel coils, and a very high temperature is maintained throughout the manufacturing process. This process is followed because the recrystallization temperature must be reached to produce stainless steel coils.

Stainless steel coils can be employed in harsh environments due to their heat and fire resistance. In addition, outstanding corrosion resistance characterizes them. Its capacity to withstand corrosion is utilized in various applications, including mills, industrial equipment, medical devices, and many more.

Choosing the Proper Stainless Steel Coil Manufacturer

To make sure you have the most positive outcome when purchasing stainless steel coils from a stainless steel coil manufacturer, it is important to compare at least 4 to 5 manufacturers using our list of stainless steel coil companies. Each stainless steel coil manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each stainless steel coil business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple stainless steel coil companies with the same quote.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services