We provide the best products in the stainless steel industry. Our customers know they can trust us for quality, affordability, and convenience. Our multiple locations make it easy to get what you need within days!

Cada Stainless is a distributor of stainless steel in strip, coil & sheet. All grades of stainless steel available- annealed, tempered in 301,302,304,316, straight and L grades, 17/4, 17/7, 420,430,440, temper rolling to specific thicknesses & tolerances available.

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

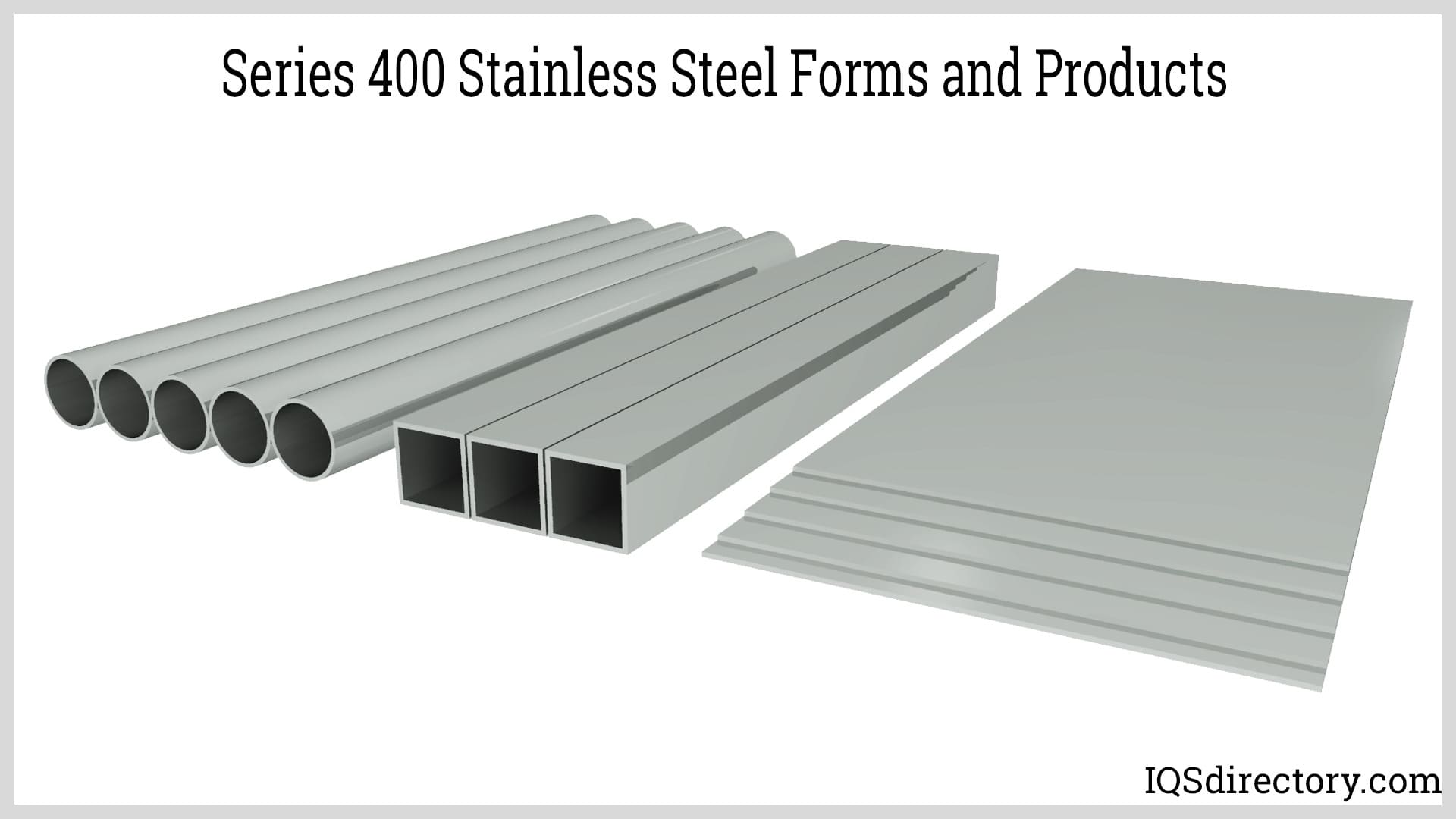

At Millennium Metals, LLC, we specialize in providing high-quality stainless steel products to meet the diverse needs of our customers across a wide range of industries. We take pride in offering an extensive inventory of stainless steel grades, shapes, and sizes, ensuring our clients have access to the materials they need, exactly when they need them.

At Alliant Metals, we dedicate ourselves to supplying high-quality stainless steel products and tailored services that meet the demands of a wide range of industries. As specialists in stainless steel, we work closely with our customers to deliver material that aligns with their exact specifications, whether the need is for standard stock or custom-cut solutions.

More Stainless Steel Alloy Manufacturers

Stainless steel is a rust and corrosion-resistant iron alloy. Stainless steel alloys often contain at least 11% chromium. The alloy gains useful qualities when adding various chemicals and metals. The chromium creates a passive layer that shields the metal and self-heals in the presence of oxygen. This creates the corrosion-resistant quality that makes stainless steel alloy useful. Stainless steel is recyclable and accommodates sustainable building requirements.

How Stainless Steel is Made

The first step in creating stainless steel is melting scrap metals and additives in an electric arc furnace (EAF). The EAF uses high-power electrodes to heat metals for hours, producing a flowing, molten mixture. The carbon makes the iron harder and stronger. However, too much carbon can lead to future issues, like carbide precipitating during welding. Before casting, it’s crucial to calibrate and reduce the carbon content of molten stainless steel to the appropriate level.

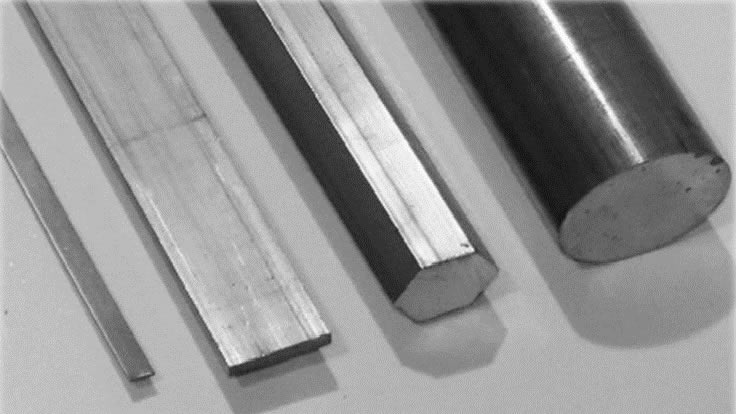

After the carbon reduction, the temperature and chemistry are balanced and homogenized to guarantee the steel's composition remains consistent throughout the batch. It also helps ensure the metal will satisfy certain grade specifications. Next, the foundry produces a simple shape to cool and work the molten steel. The finished product will determine the precise form and size.

Components of Stainless Steel Alloys

Chromium

Chromium-based stainless steel is significantly more resistant to corrosion, staining, and tarnishing.

Nickel

Nickel will improve an alloy’s ductility, weldability, and formability. Overall, nickel enhances the versatility of stainless steel.

Carbon

Stainless steel alloys with high carbon content are resilient and long-lasting. As a result, they’re commonly used for the food-grade stainless steel in cooking utensils.

Types of Stainless Steel Alloys

Ferritic Stainless Steel

Ferritic stainless steel is essentially nickel-free, with chromium making up 10.5% to 27% of it’s composition. A high chromium concentration makes the ferritic alloy corrosion and oxidation-resistant. However, because of it’s low mechanical qualities, it’s utilized as less stressed. Ferritic stainless steel is useful for high-temperature applications because of its excellent expansion coefficient and high-temperature resistance.

Martensitic Stainless Steel

Martensitic stainless steel has a chromium content between 11.5 and 18%, less than carbon, and occasionally some nickel. This alloy isn’t very ductile, but the high carbon content makes it strong, wear-resistant, and sturdy. Manufacturers use martensitic stainless steel alloys for applications requiring exceptional mechanical qualities.

Austenitic Stainless Steel

Austenitic stainless steel has over 18% chromium, 8% nickel, and minor quantities of molybdenum, titanium, nitrogen, and other elements. This alloy makes up almost 60% of all stainless steel manufacturing. Austenitic stainless steel has the best overall performance and greatest output compared to other alloys. Due to its excellent plasticity, toughness, and weldability, it’s often used for corrosion-resistant applications.

Duplex Stainless Steel

Duplex stainless steel contains roughly half Austenite and half Ferrite alloys. Typically, there’s over 30% of at least one component. To create duplex stainless steel, increase the Cr content of 18-8 austenite, or add ferrite components. Duplex stainless steels retain the Ni alloy, bidirectional austenite, and ferrite structures. This mixture overcomes the flaws of ferrite and austenite while retaining their perspective advantages. However, duplex stainless steels require a stringent procedure due to their poorer heat resistance and moderate temperature brittle zone.

Precipitation Stainless Steel

Precipitation stainless steel is created when stainless steel is combined with additional components through precipitation hardening. The mixture will determine the precise composition and characteristics of the precipitation alloy. Precipitation stainless steels are often ductile, strong, and corrosion-resistant.

To ensure long-lasting results and reduce expenses, it is crucial to understand which stainless steel grades are appropriate for different applications. There is often a stainless steel alloy to fit your needs, whether you’re seeking a robust alloy to withstand marine conditions or a beautiful alloy polished for utensil use.

Choosing the Correct Stainless Steel Alloy Manufacturer

To make sure you have the most beneficial outcome when purchasing stainless steel alloys from a stainless steel alloy manufacturer, it is important to compare at least 4 manufacturers using our stainless steel alloy directory. Each stainless steel alloy manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each stainless steel alloy business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple stainless steel alloy companies with the same message.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services