We provide the best products in the stainless steel industry. Our customers know they can trust us for quality, affordability, and convenience. Our multiple locations make it easy to get what you need within days!

Cada Stainless is a distributor of stainless steel in strip, coil & sheet. All grades of stainless steel available- annealed, tempered in 301,302,304,316, straight and L grades, 17/4, 17/7, 420,430,440, temper rolling to specific thicknesses & tolerances available.

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

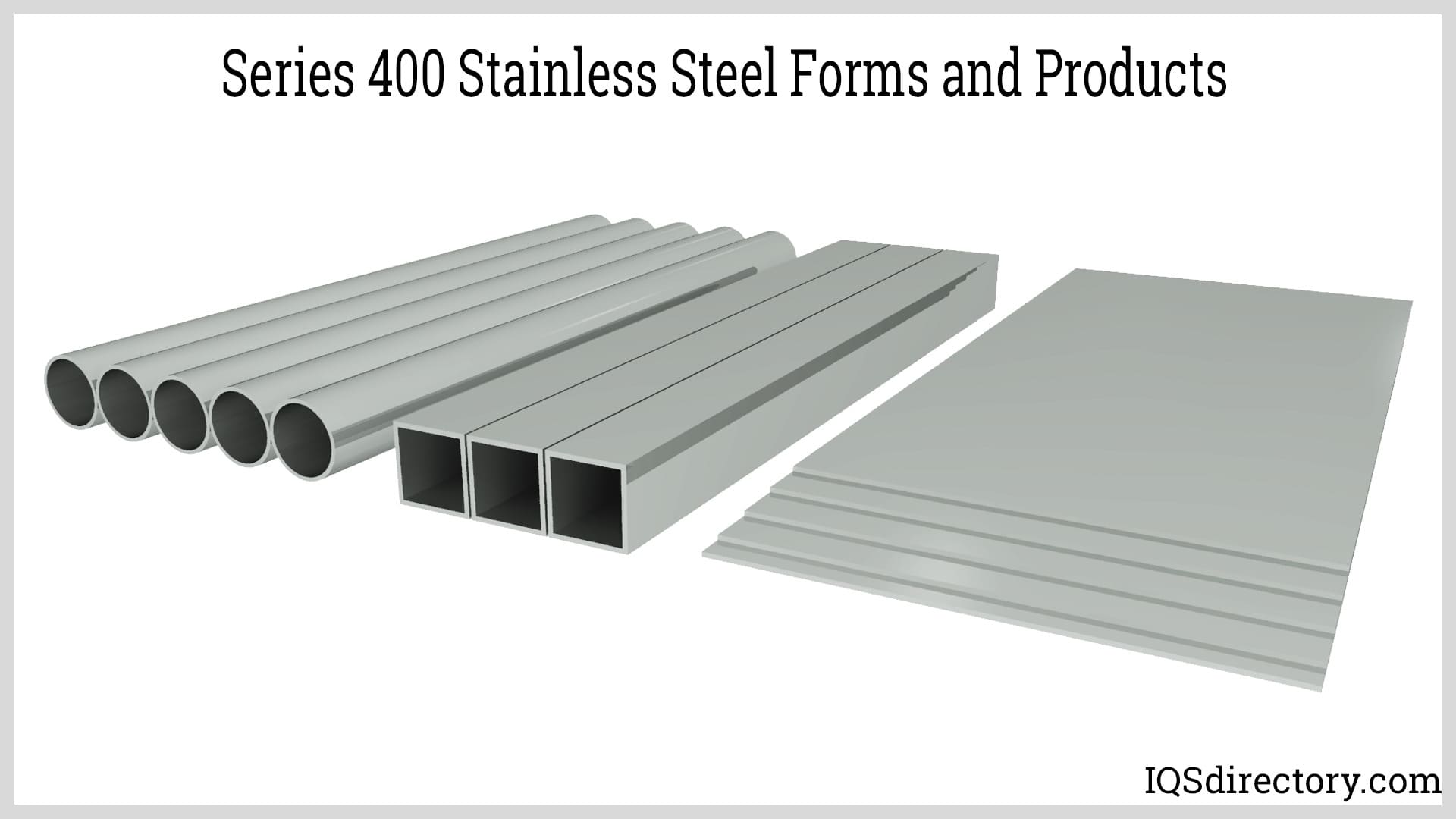

At Millennium Metals, LLC, we specialize in providing high-quality stainless steel products to meet the diverse needs of our customers across a wide range of industries. We take pride in offering an extensive inventory of stainless steel grades, shapes, and sizes, ensuring our clients have access to the materials they need, exactly when they need them.

At Alliant Metals, we dedicate ourselves to supplying high-quality stainless steel products and tailored services that meet the demands of a wide range of industries. As specialists in stainless steel, we work closely with our customers to deliver material that aligns with their exact specifications, whether the need is for standard stock or custom-cut solutions.

More Stainless Steel 304 Manufacturers

Stainless steel 304, also known as 18-8 stainless steel, is a versatile and widely used austenitic stainless steel alloy characterized by its high corrosion resistance, durability, and excellent formability. Composed of primarily iron, chromium (18%), and nickel (8%), it also contains small amounts of manganese, silicon, and other elements.

Its non-reactive and hygienic properties, coupled with its strength and ease of fabrication, make it a preferred choice for a wide range of structural and decorative purposes.

Industries That Use Stainless Steel 304

Stainless steel 304 finds applications across various industries due to its favorable properties. Here are some of the top industries that use stainless steel 304:

Food and Beverage Industry: Stainless steel 304 is a popular choice for food processing equipment, kitchen appliances, and food storage containers. Its resistance to corrosion, easy cleaning, and non-reactive properties make it ideal for ensuring food safety and hygiene.

Chemical and Pharmaceutical Industry: Stainless steel 304 is used in the manufacture of chemical processing equipment, pharmaceutical vessels, and storage tanks. Its resistance to chemical corrosion and ease of sterilization make it crucial for maintaining product purity and safety.

Oil and Gas Industry: Stainless steel 304 is employed in various components within the oil and gas sector, such as pipelines, valves, and storage tanks. Its resistance to both corrosion and high temperatures makes it a dependable choice for transporting and storing petroleum products.

Architecture and Construction: Stainless steel 304 is used in architectural elements like handrails, structural components, and building facades. Its aesthetic appeal, durability, and resistance to environmental factors make it a preferred material for modern construction projects.

Medical and Healthcare Industry: Stainless steel 304 is widely used in medical instruments, surgical tools, and equipment like hospital beds and storage units. Its biocompatibility, ease of sterilization, and resistance to body fluids make it suitable for medical applications.

Automotive Industry: Stainless steel 304 is used in automotive exhaust systems, decorative trims, and some engine components. Its resistance to heat and corrosion helps maintain the longevity and appearance of automotive parts.

Aerospace Industry: In aerospace applications, stainless steel 304 is used for components like aircraft exhaust systems, structural elements, and fasteners. Its strength-to-weight ratio and resistance to high temperatures are crucial in aviation.

Water Treatment Industry: Stainless steel 304 is employed in water treatment plants for pipes, tanks, and filtration systems. Its resistance to corrosion is essential for ensuring the longevity and effectiveness of water treatment equipment.

Marine Industry: Stainless steel 304 is used in marine applications such as boat fittings, shipbuilding, and offshore structures. Its resistance to saltwater corrosion makes it an ideal choice for marine environments.

Renewable Energy Industry: Stainless steel 304 is used in renewable energy applications, including wind turbine components and solar panel mounts. Its corrosion resistance helps ensure the durability of these components in outdoor environments.

How to Find a Stainless Steel 304 Manufacturer

When purchasing stainless steel 304 from a stainless steel 304 manufacturer, it is important to compare at least 4 or 5 manufacturers using our list of stainless steel 304 manufacturers. Each stainless steel 304 manufacturer has a business profile page that highlights their areas of experience and capabilities, and has a contact form to directly communicate with the manufacturer for more information or request a quote. Review each stainless steel 304 manufacturer's website using our proprietary website previewer to get an idea of what each manufacturer specializes in, and then use our simple RFQ form to contact multiple stainless steel 304 manufacturers with the same quote.

Choosing the right stainless steel 304 manufacturer for your specific industry is crucial to ensure that you receive high-quality materials that meet your specific needs and standards. Here are some steps to help you select the right manufacturer:

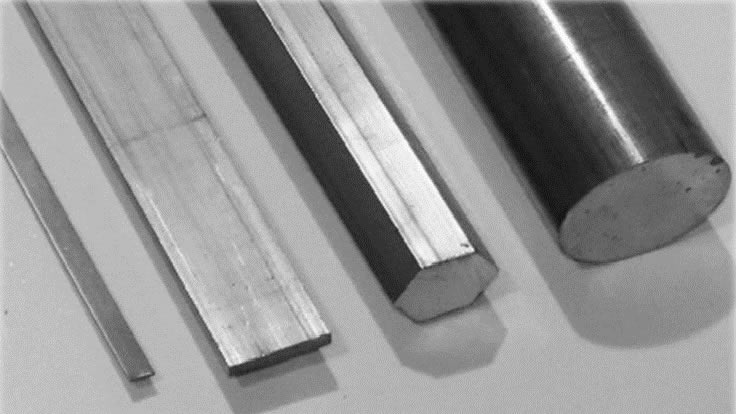

Identify Your Industry Requirements: Start by clearly defining your industry's specific requirements for stainless steel 304. Consider factors like the grade of stainless steel, size, shape, quantity, and any unique specifications that are relevant to your application.

Research Potential Manufacturers: Look for stainless steel 304 manufacturers who have a strong reputation and experience in serving your industry. You can find potential manufacturers through online searches, industry directories, trade associations, and recommendations from colleagues or industry experts.

Assess Quality and Certifications: Check if the manufacturer complies with industry standards and holds relevant certifications such as ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and ISO 45001 (Occupational Health and Safety). Additionally, ensure that they provide materials that meet ASTM or other industry-specific standards.

Quality Control and Testing: Inquire about the manufacturer's quality control processes and testing procedures. They should be able to provide documentation of quality assurance measures and the results of material testing.

Production Capacity and Lead Times: Evaluate the manufacturer's production capacity to ensure they can meet your order volume requirements. Additionally, discuss lead times to ensure that they can deliver products within your project's timeline.

Customization and Fabrication Services: Determine if the manufacturer offers customization and fabrication services to meet your specific needs. This is especially important if you require stainless steel components with unique shapes or sizes.

Cost and Pricing Structure: Request detailed price quotes from multiple manufacturers and compare their pricing structure. Keep in mind that while cost is important, it should not be the sole determining factor. High-quality materials may cost more upfront but can save money in the long run.

Supplier's Location and Logistics: Consider the manufacturer's location in relation to your facility. Proximity can affect shipping costs and lead times. Additionally, assess their logistics capabilities to ensure timely delivery.

References and Reviews: Ask the manufacturer for references or case studies from clients in your industry. Reading reviews and testimonials can also provide insights into their performance and customer satisfaction.

Communication and Support: Evaluate the manufacturer's communication and customer support. A responsive and helpful manufacturer can make the procurement process smoother and more efficient.

Sustainability and Environmental Practices: If sustainability is a concern for your industry, inquire about the manufacturer's environmental practices, such as recycling and waste reduction initiatives.

Long-Term Relationship: Consider the potential for a long-term partnership. A manufacturer that understands your industry's evolving needs and can adapt to changes is valuable for sustained success.

By thoroughly researching and evaluating potential stainless steel 304 manufacturers using these criteria, you can make an informed decision that aligns with your quality, cost, and production needs.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services