We provide the best products in the stainless steel industry. Our customers know they can trust us for quality, affordability, and convenience. Our multiple locations make it easy to get what you need within days!

Cada Stainless is a distributor of stainless steel in strip, coil & sheet. All grades of stainless steel available- annealed, tempered in 301,302,304,316, straight and L grades, 17/4, 17/7, 420,430,440, temper rolling to specific thicknesses & tolerances available.

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

At Millennium Metals, LLC, we specialize in providing high-quality stainless steel products to meet the diverse needs of our customers across a wide range of industries. We take pride in offering an extensive inventory of stainless steel grades, shapes, and sizes, ensuring our clients have access to the materials they need, exactly when they need them.

At Alliant Metals, we dedicate ourselves to supplying high-quality stainless steel products and tailored services that meet the demands of a wide range of industries. As specialists in stainless steel, we work closely with our customers to deliver material that aligns with their exact specifications, whether the need is for standard stock or custom-cut solutions.

More Stainless Steel Grade Manufacturers

Of all the different series, the 200, 300 and 400 series are the most common. Stainless steel is graded through consideration of the environment that it will be assigned to.

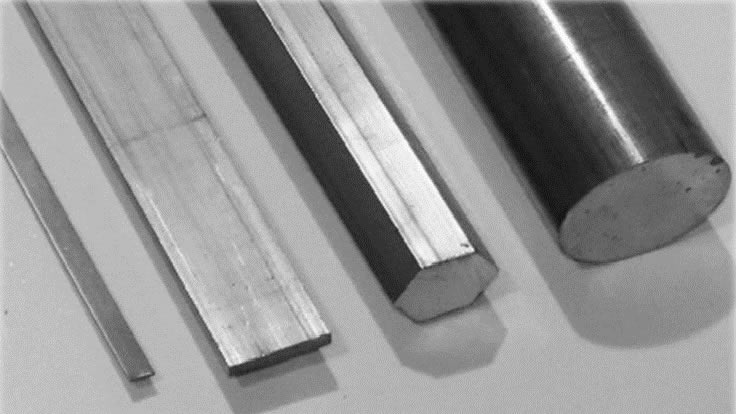

The typical stainless steel grading system used for stainless steel is the Society of Automotive Engineers (SAE) Grades, which is designated by the SAE, and the UNS grades. Since stainless steel is an iron-based alloy, stainless steel grades contain a minimum of 11% chromium. In addition to chromium, alloys such as molybdenum, copper and titanium may be added to amplify certain properties.

Some overarching characteristics of stainless steel include corrosion-resistance, high ductility, weldability and cryogenic toughness. Another benefit of stainless steel grades is that they are totally recyclable, creating increasing demand amongst environmentally-friendly consumers.

Additionally, stainless steel grades have wide-ranging applications such as consumer appliances, automotive exhausts, surgical instruments, heaters, valves, knife blades, chemical tanks, heat exchangers and spring clips. As a result, stainless steel grades are utilized in numerous industries including medical, automotive, manufacturing, aerospace, printing, marine and petrochemical.

The different series of stainless steel grades all have unique characteristics. The 100 through the 300 series are all various grades of austenitic stainless steel, which is the most common type of stainless steel in production. Some characteristics that are unique to the 100 series include the composition of austenitic chromium-nickel-manganese alloys that are available in two types: type 101, which can be hardened through cold working; and type 102, which is a more general purpose type of stainless steel. Both types are often used in furniture. The 200 series is also composed of austenitic chromium-nickel-manganese alloys, although the percentages differ.

This series includes type 201 and type 202, which mirror the 100 series types. The 300 series is the largest series and are composed of austenitic chromium-nickel alloys. Some types within these series feature the addition of molybdenum for increased corrosion resistance and changing carbon content depending on their designated environment. Types 304 and 316 are the most common types in the 300 series.

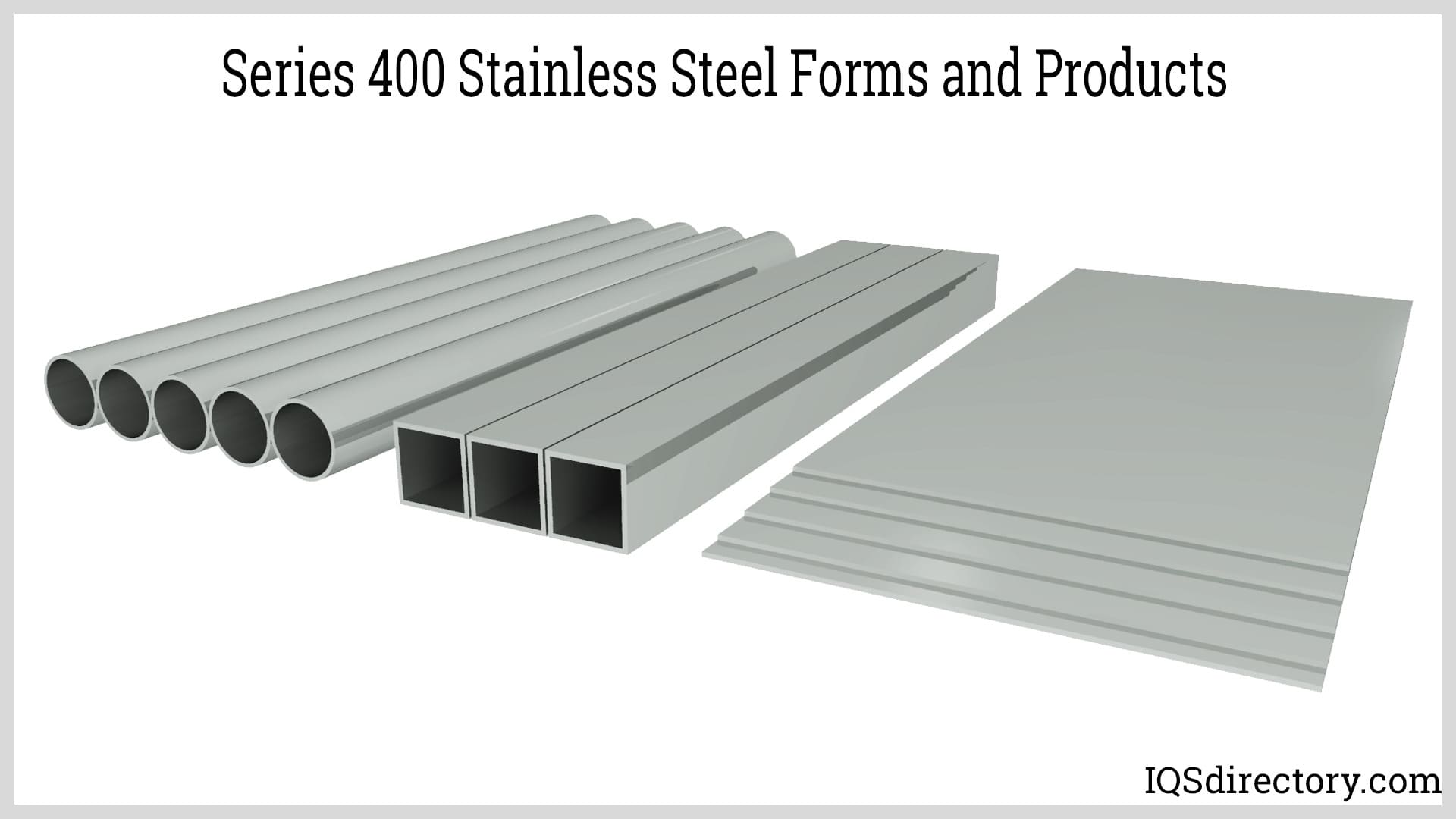

The 400 series includes various grades of ferritic and martensitic stainless steel and are all composed of chromium alloys. The types of stainless steel in this series are magnetic and typically contain 11% chromium and 1% manganese. The 500 series consists of heat-resistant chromium alloys and is not very large or commonly used. Lastly, the 600 series consists of martensitic precipitation-hardening alloys that can undergo heat treatment and attain high strength levels.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services