We provide the best products in the stainless steel industry. Our customers know they can trust us for quality, affordability, and convenience. Our multiple locations make it easy to get what you need within days!

Cada Stainless is a distributor of stainless steel in strip, coil & sheet. All grades of stainless steel available- annealed, tempered in 301,302,304,316, straight and L grades, 17/4, 17/7, 420,430,440, temper rolling to specific thicknesses & tolerances available.

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

At Millennium Metals, LLC, we specialize in providing high-quality stainless steel products to meet the diverse needs of our customers across a wide range of industries. We take pride in offering an extensive inventory of stainless steel grades, shapes, and sizes, ensuring our clients have access to the materials they need, exactly when they need them.

At Alliant Metals, we dedicate ourselves to supplying high-quality stainless steel products and tailored services that meet the demands of a wide range of industries. As specialists in stainless steel, we work closely with our customers to deliver material that aligns with their exact specifications, whether the need is for standard stock or custom-cut solutions.

More Stainless Steel Bar Manufacturers

Stainless steel bars are essential components in modern engineering, construction, manufacturing, and fabrication industries. Each stainless steel bar is composed primarily of iron combined with two or more chemical elements—a composition known as an alloy. The addition of elements such as chromium, nickel, and molybdenum enhances the bar’s corrosion resistance, mechanical strength, and durability. Particularly, a high chromium content, typically at least 10.5%, is what imparts stainless steel its exceptional ability to resist rust, oxidation, and staining, making it suitable for demanding environments.

Major stainless steel manufacturers offer a wide array of proprietary alloys in addition to the 57 standard stainless steel alloys defined by ASTM standards. This diversity ensures that buyers and engineers can specify precisely the right grade and form for their project requirements. Stainless steel bars are renowned for their versatility, finding applications in architectural exteriors, building roofs, bulk material handling equipment, vehicle parts, medical devices, food processing equipment, marine applications, and much more.

Manufacturing of Stainless-Steel Bars: Process, Grades, and Quality Control

The production process for stainless steel bars involves several meticulous stages to ensure optimal material properties and performance. The manufacturing begins with melting a precise blend of iron ore, chromium, silicon, nickel, and other alloying elements in an electric arc furnace. This melting stage, often lasting 8 to 12 hours at extremely high temperatures, results in a molten alloy with uniform composition.

After melting, the molten stainless steel is either quenched—rapidly cooled—to yield a harder material, or air-hardened for a softer, more ductile product. The cooling process, a critical phase in metallurgy, directly influences the microstructure and final mechanical properties of the bar. Once cooled, the steel undergoes descaling via pickling or electrocleaning to remove surface oxides and scale, ensuring a clean, smooth finish.

Next, the steel is cut to the desired dimensions using methods such as shearing, blanking, nibbling, or flame cutting. This is followed by further processing steps—including hot rolling, cold rolling, annealing, and additional descaling—to achieve specific surface finishes, dimensional tolerances, and mechanical properties. These secondary processes are vital for meeting the diverse requirements of industries such as automotive manufacturing, construction, and precision engineering.

Most commonly, stainless steel bars are produced in standard grades such as 304 and 316 stainless steel. These grades are selected based on their unique chemical makeup, corrosion resistance, mechanical properties, and suitability for various applications.

What Are the Main Grades of Stainless Steel Bars?

- 304 Stainless Steel Bar: The most widely used austenitic stainless steel, valued for its excellent corrosion resistance, formability, and weldability. Ideal for general-purpose applications and food processing.

- 304L Stainless Steel Bar: A low-carbon variant of 304, preferred for welded structures where resistance to intergranular corrosion is critical.

- 316 Stainless Steel Bar: Enhanced with added molybdenum and nickel, offering superior resistance to chlorides, acids, and marine environments. Widely chosen for chemical processing, marine, and pharmaceutical uses.

- 316L Stainless Steel Bar: The low-carbon version of 316, designed for increased weldability and corrosion resistance, especially in harsh and corrosive environments.

- Other Grades: Specialty grades such as 410, 416, 420, and duplex stainless steels are available for specific industrial requirements, including higher hardness, machinability, or pitting resistance.

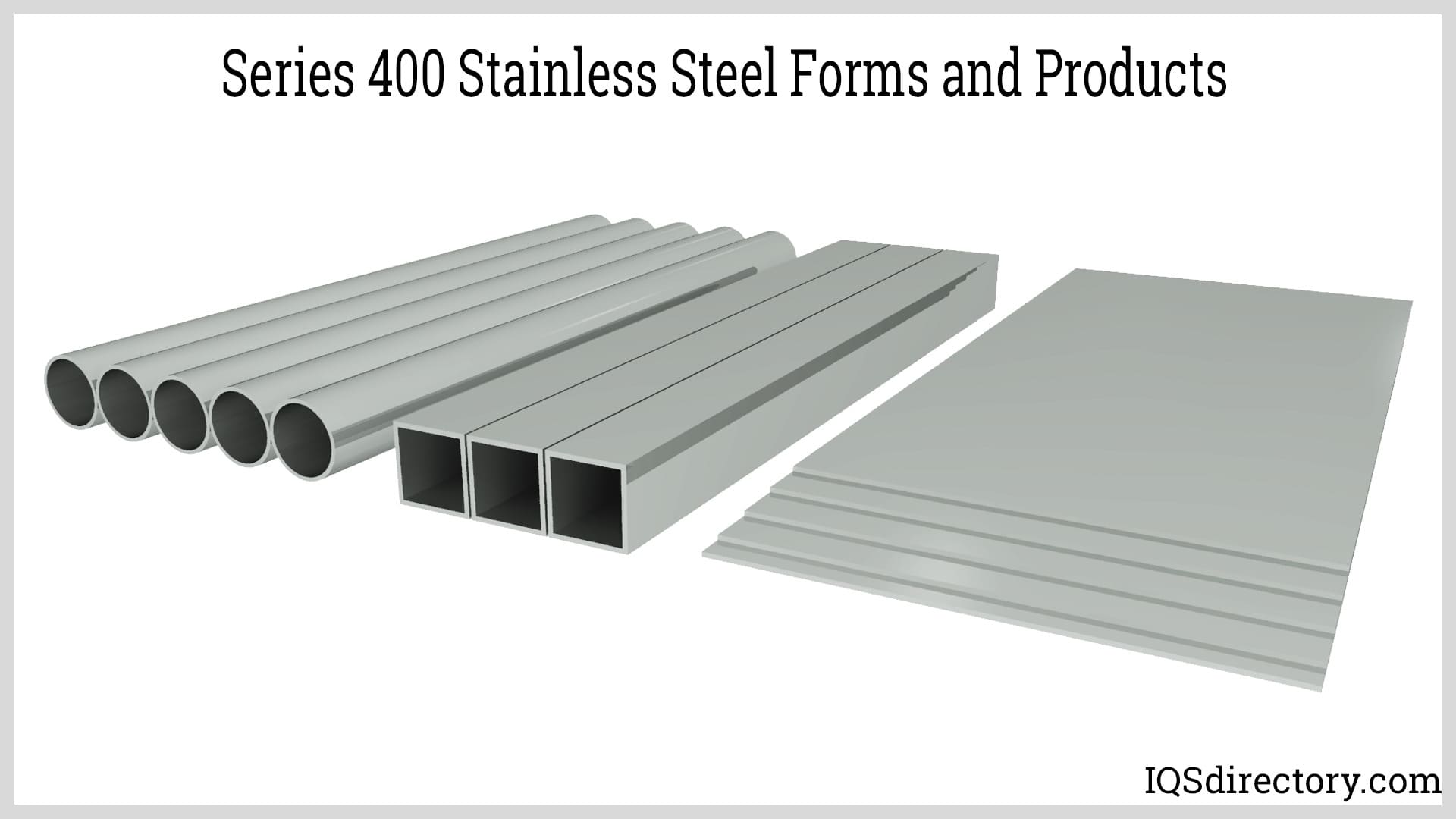

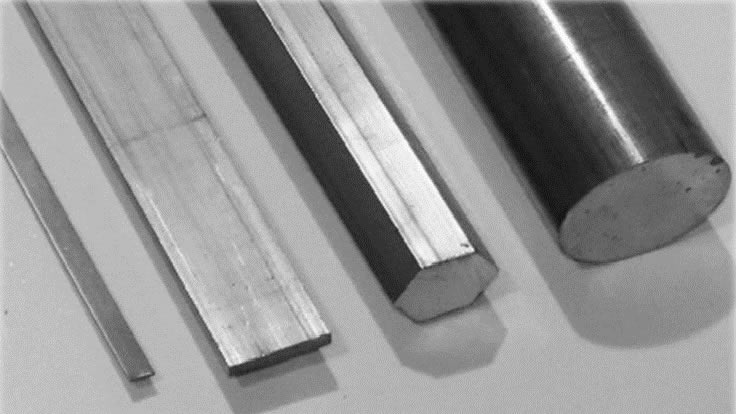

Shapes of Steel Bars: Which Type Best Suits Your Application?

Stainless steel bars are manufactured in a variety of shapes and cross-sections to support different structural and functional needs. Choosing the right shape is a crucial decision for engineers and procurement specialists, as it impacts performance, ease of fabrication, and cost-efficiency. The four most common types are flat bars, round bars, hexagonal bars, and square bars, each offering unique advantages for specific applications.

Flat Stainless Steel Bars: Strength, Versatility, and Common Uses

Flat stainless-steel bars are hot rolled to achieve a thick, robust, and highly corrosion-resistant profile. They are commonly available in grades 304 stainless steel and 316, with 316 being an upgraded alloy due to its higher molybdenum and nickel content. This makes 316 stainless flat bars especially valuable for use in severe environments such as chemical processing plants, marine infrastructure, and outdoor architectural projects.

Molybdenum in 316 stainless steel greatly enhances resistance against acetic acid vapors, seawater, and chloride-laden atmospheres, ensuring the metal maintains its structural integrity and aesthetic appearance even in the presence of saltwater or industrial pollutants. For applications involving welding in corrosive environments, the lower carbon 316L variant is recommended to minimize carbide precipitation and maximize corrosion resistance.

304 stainless steel flat bars are known for their all-purpose adaptability, combining affordability with outstanding corrosion resistance, mechanical strength, and ease of fabrication. This grade is the industry standard for food processing, kitchen equipment, and architectural trim. When there is a risk of intergranular corrosion in the heat-affected zone—such as in welded assemblies—304L stainless steel is preferred for its enhanced stability.

Typical applications for flat stainless steel bars include:

- Architectural features: Handrails, balustrades, window and door frames

- Industrial manufacturing: Conveyor belts, machine parts, support brackets

- Automotive: Chassis components, decorative trims

- Marine hardware: Boat fittings, dock cleats, ladders

- Food processing: Table surfaces, storage racks, mixing equipment

- Medical devices: Instrument trays, mounting brackets

- Ornaments and consumer goods: Jewelry, dental braces, handles, and fixtures

Round Stainless Steel Bars: Precision, Machinability, and Key Applications

Round stainless steel bars are prized for their excellent machinability and uniform cross-section, making them the go-to choice for manufacturing machine parts, fasteners, and automotive components. The production process starts with casting molten steel into billets, which are then hot-rolled and drawn into precise round profiles. The resulting bars are easy to cut, shape, and thread, making them indispensable in industries that demand tight tolerances and high surface quality.

Due to their superior corrosion resistance and high tensile strength, round stainless steel bars are commonly used in:

- Machining and fabrication: Shafts, axles, spindles, gears, and pins

- Automotive industry: Engine parts, suspension components, exhaust systems

- Construction: Anchor bolts, studs, reinforcement rods

- Oil & gas: Valve stems, connectors, drilling tools

- Medical engineering: Orthopedic implants, surgical instruments

- Food processing: Mixing paddles, cutters, extruders

Wondering which stainless steel round bar is best for your project? Contact leading suppliers to compare availability, pricing, and custom machining services.

Hexagonal Stainless Steel Bars: Load-Bearing and Mechanical Performance

Hexagonal bars—also known as hex bars—are engineered for maximum load-bearing capability and are often used where space, weight, and strength considerations are paramount. Their unique six-sided profile provides increased torque transmission, making them ideal for use as fasteners, shafts, and connectors in construction, heavy machinery, and automotive assemblies.

Common applications include:

- Construction hardware: Nuts, bolts, and threaded rods

- Machinery manufacturing: Couplings, spacers, drive shafts

- Aerospace and defense: Fastener systems, support frames

- Engineering projects: Custom components requiring a precise, strong profile

Square Stainless Steel Bars: Strength, Durability, and Industrial Use

Square stainless steel bars are valued for their exceptional strength, rigidity, and versatility. Their uniform, four-sided profile makes them suitable as medium or large parts in industrial machinery, structural frameworks, and fabrication projects.

Typical use cases include:

- Structural engineering: Columns, braces, and support beams

- Manufacturing: Machine frames, jigs, fixtures, and tooling bars

- Automotive and transportation: Brackets, chassis parts, bumpers

- General fabrication: Welded assemblies, custom cut pieces

Looking for custom-cut square stainless steel bar stock? Request quotes from multiple suppliers to find the best lead times and pricing for your specifications.

Key Benefits of Stainless Steel Bars

Why are stainless steel bars the preferred choice for so many industries? Their unique properties deliver substantial advantages:

- Corrosion resistance: Ideal for exposure to moisture, chemicals, and harsh weather. Stainless steel's protective oxide layer inhibits rust and staining, even in marine or caustic environments.

- High strength-to-weight ratio: Allows for lighter, more efficient structures without compromising safety or performance.

- Long service life: Lowers total cost of ownership by reducing maintenance, downtime, and replacement intervals.

- Excellent machinability and weldability: Facilitates easier fabrication, complex assemblies, and custom modifications.

- Hygienic properties: Non-porous, easy-to-clean surfaces make stainless steel bars a top choice for food processing, pharmaceuticals, and healthcare equipment.

- Recyclability: Stainless steel is 100% recyclable, supporting sustainability initiatives and green building certifications.

- Aesthetic appeal: Sleek, modern appearance suitable for visible architectural elements and consumer products.

Have more questions about stainless steel bar properties? Explore our resource library or contact technical experts for guidance on grade selection and performance characteristics.

How to Choose the Right Stainless Steel Bar for Your Project

With so many grades, shapes, and finishes available, selecting the right stainless steel bar can feel overwhelming. Here are the key factors to consider as you compare products and suppliers:

- Application requirements: Will the bar be used in corrosive, high-temperature, high-stress, or hygienic environments?

- Required mechanical properties: Consider tensile strength, hardness, ductility, and impact resistance.

- Grade selection: 304 and 316 are most common, but specialty grades may be needed for extreme conditions or specific industry standards.

- Shape and dimensions: Flat, round, hexagonal, and square bars all serve distinct functions and have unique fabrication requirements.

- Surface finish: Satin, mirror, and brushed finishes can affect appearance, corrosion resistance, and cleanability.

- Certification and traceability: Ensure your bars meet ASTM, ASME, or ISO standards, with full mill test reports and traceability for regulated industries.

- Supplier reputation: Work with established stainless steel bar manufacturers or distributors who offer quality assurance and responsive customer support.

Not sure which stainless steel bar grade or shape is ideal for your needs? Ask these questions when talking to suppliers:

- Which stainless steel bar grade is best for my application’s corrosion resistance needs?

- Can you provide custom cutting, machining, or finishing services?

- Do you offer mill test certificates and compliance documentation?

- What are your lead times and minimum order quantities?

- Are there bulk pricing or volume discounts available?

- Can I get samples for testing?

Applications of Stainless Steel Bars Across Industries

Stainless steel bars are integral to countless products, structures, and systems. Their unique combination of corrosion resistance, strength, and workability means they are found in:

- Commercial and residential construction: Support beams, handrails, architectural trim, rebar, and fasteners

- Automotive and transportation: Engine components, chassis parts, axles, and mounting brackets

- Marine and offshore: Ship fittings, propeller shafts, dock hardware, and anchoring systems

- Food and beverage processing: Conveyor systems, mixers, tables, and hygienic storage solutions

- Medical and pharmaceutical: Surgical instruments, hospital furniture, cleanroom equipment

- Industrial manufacturing: Machinery frames, fixtures, shafts, gears, and tooling parts

- Energy and petrochemical: Valve stems, pump shafts, connectors, refinery supports

- Aerospace and defense: Fasteners, structural supports, landing gear components

Curious about how stainless steel bars are integrated into your specific sector? Search our industry case studies for real-world examples and best practices.

Choosing the Right Stainless Steel Bar Company: Your Supplier Checklist

To ensure you achieve optimal results when purchasing stainless steel bars, it’s essential to compare multiple suppliers and evaluate their capabilities closely. The right stainless steel bar supplier will deliver not only high-quality products but also value-added services and technical support.

Here’s how to streamline your supplier selection process:

- Compare at least five companies using our comprehensive stainless steel bar directory.

- Review business profiles to assess areas of expertise, inventory, and manufacturing capabilities.

- Contact directly using our built-in forms to request quotes, technical information, or sample orders.

- Preview company websites with our proprietary website previewer to identify specializations and certifications.

- Submit a single RFQ (Request for Quote) form to contact multiple suppliers with your requirements.

- Evaluate customer service, lead times, and after-sales support in addition to pricing.

- Request mill certificates and compliance documents for regulated industries.

Ready to find the best stainless steel bar supplier for your project? Compare top-rated manufacturers now or request a custom quote for your specific needs.

Frequently Asked Questions: Stainless Steel Bars

- What is the difference between 304 and 316 stainless steel bars?

304 stainless steel offers excellent corrosion resistance and affordability, making it the go-to grade for most general applications. 316 stainless steel, with added molybdenum, delivers superior resistance against chlorides and is preferred for marine or chemical exposure. - How do I select the correct bar shape for my application?

The choice between flat, round, hexagonal, and square bars depends on load requirements, fabrication processes, and intended use. Consult with suppliers or engineers to match shape to application needs. - Can stainless steel bars be custom cut or machined?

Yes, most suppliers offer custom cutting, machining, and finishing services to meet precise specifications. - Are stainless steel bars magnetic?

Austenitic grades like 304 and 316 are generally non-magnetic in the annealed condition, though cold working can induce some magnetism. Ferritic and martensitic grades are typically magnetic. - What certifications should I look for?

Look for compliance with ASTM, ASME, or ISO standards, plus mill test reports for traceability. - How sustainable is stainless steel?

Stainless steel is 100% recyclable, with most new material containing significant recycled content.

Take the Next Step: Source Stainless Steel Bars with Confidence

Whether you’re an engineer specifying high-performance stainless steel bars for a critical project, a procurement manager seeking bulk order pricing, or a fabricator looking for custom machining, the key to success is partnering with the right supplier. Use our directory to compare manufacturers, review product options, and access technical support. From round bar stock to flat bar profiles, discover the full range of stainless steel bar solutions tailored to your application.

Ready to get started? Contact top stainless steel bar suppliers today or request a quote for your next project. For more technical resources, explore our stainless steel knowledge base or ask an expert for detailed guidance on material selection.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services