We provide the best products in the stainless steel industry. Our customers know they can trust us for quality, affordability, and convenience. Our multiple locations make it easy to get what you need within days!

Cada Stainless is a distributor of stainless steel in strip, coil & sheet. All grades of stainless steel available- annealed, tempered in 301,302,304,316, straight and L grades, 17/4, 17/7, 420,430,440, temper rolling to specific thicknesses & tolerances available.

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

We are Liberty Specialty Metals, and we specialize in supplying high-performance stainless steel solutions for demanding industrial and commercial applications. Our focus is on delivering premium stainless steel materials that meet exacting standards for strength, corrosion resistance, and long-term reliability.

At Millennium Metals, LLC, we specialize in providing high-quality stainless steel products to meet the diverse needs of our customers across a wide range of industries. We take pride in offering an extensive inventory of stainless steel grades, shapes, and sizes, ensuring our clients have access to the materials they need, exactly when they need them.

At Alliant Metals, we dedicate ourselves to supplying high-quality stainless steel products and tailored services that meet the demands of a wide range of industries. As specialists in stainless steel, we work closely with our customers to deliver material that aligns with their exact specifications, whether the need is for standard stock or custom-cut solutions.

More 420 Stainless Steel Manufacturers

420 Stainless Steel: Properties, Machining, Applications, and Supplier Selection Guide

420 stainless steel, also known as UNS S42000, is a high-carbon martensitic stainless steel recognized for its exceptional hardness, moderate corrosion resistance, and excellent wear resistance. With a minimum chromium content of 12%, 420 stainless steel is widely utilized across industries that demand a strong balance of durability and resistance to environmental factors. Its unique combination of mechanical properties makes it a popular choice for cutting tools, surgical instruments, and industrial components. Understanding the characteristics, machining processes, and key applications of 420 stainless steel can help buyers, engineers, and procurement professionals make informed decisions when sourcing materials for critical projects.

What is 420 Stainless Steel?

420 stainless steel is part of the martensitic stainless steel family, which is known for its ability to be hardened through heat treatment. This grade contains approximately 0.15% to 0.40% carbon and at least 12% chromium, giving it notable hardness and moderate resistance to corrosion, especially when compared to austenitic grades like 316 stainless steel or 304 stainless steel. Its chemical composition enables it to achieve a higher level of hardness than most other stainless steels, making it highly suitable for applications where sharpness and edge retention are priorities.

Key Properties of 420 Stainless Steel

- High Hardness: Can be hardened to a Rockwell hardness of up to 50 HRC or higher, depending on heat treatment.

- Moderate Corrosion Resistance: Resistant to mild acids, fresh water, foods, alkalis, and atmospheric conditions, but less so than austenitic or ferritic stainless steels.

- Good Ductility: When annealed, 420 stainless steel offers excellent ductility, allowing it to be formed and shaped prior to final heat treatment.

- Wear Resistance: Its high carbon content and ability to be hardened make it wear resistant, ideal for cutting tools and blades.

- Magnetic: Like most martensitic steels, 420 is magnetic in both annealed and hardened conditions.

Machining 420 Stainless Steel: Techniques, Challenges, and Tips

The machinability of 420 stainless steel largely depends on its condition—whether annealed or hardened. Generally, it is easier to machine in its soft, annealed state, but heat treatment may be used to achieve maximum hardness and wear resistance for end-use applications.

Annealing Process for 420 Stainless Steel

The annealing process for 420 stainless steel involves heating the steel above 800°C (1472°F), holding it at that temperature, and then gradually cooling it in a furnace to below 600°C (1112°F) before air cooling. This process relieves internal stresses, increases ductility, and prepares the steel for machining, forming, or further processing.

Welding and Fabrication

When welding 420 stainless steel, preheating to 150°C–320°C (302°F–608°F) is recommended, followed by heating at 610°C–760°C (1130°F–1400°F) during the welding procedure. Use of grade 309 filler rods is common to promote ductile welds. Post-weld annealing is often necessary to restore corrosion resistance and relieve stresses. It's important to note that 420 stainless steel is most easily worked in its annealed condition; however, welding can reduce its corrosion resistance compared to its hardened form.

Corrosion Resistance in Machined Parts

Although 420 stainless steel provides good resistance to food acids, fresh water, air, and mild chemicals, it is less resistant than other stainless steels such as 316 or 304. This is especially true in the annealed condition, where corrosion resistance may deteriorate, particularly in aggressive environments or with prolonged exposure to harsh substances. For applications requiring high corrosion resistance, consider passivation or protective coatings, and ensure regular cleaning if the steel is exposed to chloride-rich or acidic environments.

Machining Tips and Best Practices

- Always use sharp, high-speed steel or carbide tooling to minimize work hardening.

- Employ adequate lubrication and coolant to prevent heat buildup and tool wear.

- Maintain slow to moderate cutting speeds and feeds to reduce risk of tool chipping.

- Anneal the material prior to machining for improved ductility and machinability.

- For tight tolerances and fine finishes, consider grinding or polishing after heat treatment.

420 Stainless Steel: Common Applications and Use Cases

420 stainless steel is renowned for its hardness and edge retention, making it a go-to material for various demanding applications. Its versatility extends to industries ranging from food processing and medical to automotive and industrial manufacturing. Are you evaluating which grade of stainless steel is best for your application? Explore the following uses of 420 stainless steel to determine if it aligns with your engineering or manufacturing needs.

Key Applications of 420 Stainless Steel

- Cutlery and Blades: Used extensively in manufacturing carving knives, table knives, scissors, and industrial machine blades due to its ability to be sharpened to a fine edge and retain hardness.

- Medical Instruments: Preferred for surgical tools, dental instruments, and syringe valves, as its hardness and corrosion resistance allow for repeated sterilization and use in clinical settings.

- Shear Blades and Cutting Tools: Its wear resistance makes it ideal for shear blades, scissors, and other tools requiring long service life and easy sharpening.

- Pump Components: Used in diesel engine pump parts and valves, especially where abrasion resistance is necessary and the environment is non-chlorinated.

- Industrial Components: Employed in fasteners, shafts, and springs where moderate corrosion resistance and high mechanical strength are essential.

- Sporting Goods: Utilized in high-end razor blades, hunting knives, and precision tools for outdoor activities.

Specialized Uses and Industry Sectors

In addition to its widespread use in cutlery and medical sectors, 420 stainless steel is also found in:

- Automotive: Transmission components, valve parts, and other engine components that require high strength and moderate corrosion resistance.

- Food Processing: Equipment and surfaces exposed to food acids and moisture, where hygiene and edge retention are critical.

- Construction: Decorative trims, fasteners, and architectural hardware where appearance and wear resistance matter.

- Energy and Power: Used in turbine blades, pump shafts, and valves exposed to moderate corrosive agents.

Advantages and Limitations of 420 Stainless Steel

When selecting materials for your project, it’s critical to weigh the advantages and limitations of 420 stainless steel against other available alloys. Not sure if 420 is the right stainless steel for your needs? Consider these factors:

Advantages

- High Hardness and Strength: Achieves superior hardness after heat treatment, making it suitable for demanding wear applications.

- Edge Retention: Maintains a sharp edge, ideal for blades and cutting implements.

- Moderate Corrosion Resistance: Suitable for many non-aggressive environments, especially in the hardened state.

- Cost-Effective: More affordable than higher alloyed stainless steels like 440C, offering a good balance of performance and price.

- Versatility: Can be heat treated to reach a wide range of mechanical properties for different industrial requirements.

Limitations

- Lower Corrosion Resistance: Not ideal for marine or chloride-rich environments; prolonged exposure to harsh chemicals can cause pitting or corrosion.

- Difficult to Weld: Welding can reduce corrosion resistance and mechanical properties if not properly post-treated.

- Work Hardening: Tends to harden rapidly during machining, which may require specialized cutting tools and techniques.

- Magnetic Properties: May not be suitable for applications that require non-magnetic materials.

420 vs. Other Stainless Steel Grades: Which is Right for You?

Choosing the optimal stainless steel grade depends on your application’s requirements for hardness, corrosion resistance, machinability, and cost. Compare 420 to other common grades:

- 420 vs. 304 Stainless Steel: 304 offers superior corrosion resistance but cannot be hardened to the same degree as 420, making it less suitable for cutting tools.

- 420 vs. 316 Stainless Steel: 316 is preferred in marine and chemical environments due to its molybdenum content and higher corrosion resistance, but 420 is harder and better for edge retention.

- 420 vs. 440C Stainless Steel: 440C provides even greater hardness and wear resistance than 420, but is more expensive and may be over-specified for many common applications.

Looking for guidance on grade selection? Learn more about 316 stainless steel and how it compares to 420.

How to Source 420 Stainless Steel: Supplier Selection Criteria

When sourcing 420 stainless steel for your manufacturing, engineering, or fabrication needs, it is crucial to partner with a reputable and experienced supplier. Here’s how to ensure you select the right 420 stainless steel supplier for your project:

Steps to Choose a Quality 420 Stainless Steel Supplier

- Compare Multiple Suppliers: Evaluate and compare at least four suppliers to ensure competitive pricing, availability, and quality standards.

- Review Capabilities: Check each supplier’s business profile, manufacturing capabilities, certifications (such as ISO 9001), and track record with 420 stainless steel materials.

- Request Material Certifications: Ensure the supplier provides full traceability and test reports for each batch of 420 stainless steel supplied.

- Assess Technical Support: Look for suppliers who can offer technical guidance on grades, heat treatments, and machining best practices specific to your requirements.

- Utilize Online Resources: Use business directories and supplier comparison tools, such as the list of 316 stainless steel companies, to review profiles and reach out for quotes.

- Request Samples: Before committing to large orders, ask for material samples to evaluate quality and suitability for your application.

Each 420 stainless steel supplier featured online typically has a detailed business profile highlighting their experience, specialties, and capabilities. Use the provided contact forms to communicate directly with suppliers, request quotes, or inquire about custom solutions. You can also take advantage of website previewers to review supplier websites and gain insights into their product offerings before submitting a Request for Quote (RFQ) to multiple suppliers simultaneously.

Key Questions to Ask When Researching 420 Stainless Steel Suppliers

- What is your minimum order quantity for 420 stainless steel bars, sheets, or custom components?

- Do you offer additional processing services, such as cutting, grinding, or heat treatment?

- Can you provide full material traceability and certification for your 420 stainless steel products?

- What are your lead times for stock and custom orders?

- How do you ensure consistent quality and compliance with industry standards?

Frequently Asked Questions About 420 Stainless Steel

Is 420 stainless steel food safe?

Yes, 420 stainless steel is considered food safe and is commonly used in kitchen knives and food processing equipment. However, prolonged contact with acidic or salty foods can lead to pitting corrosion. Regular cleaning and drying are advised to maintain performance.

Can 420 stainless steel be heat treated?

Absolutely. 420 stainless steel can be hardened by heat treatment, which involves heating, quenching, and tempering to achieve the desired balance of hardness and toughness. The typical hardness achieved is between 48-56 HRC.

Is 420 stainless steel magnetic?

Yes, as a martensitic grade, 420 stainless steel is magnetic in all conditions, both annealed and hardened.

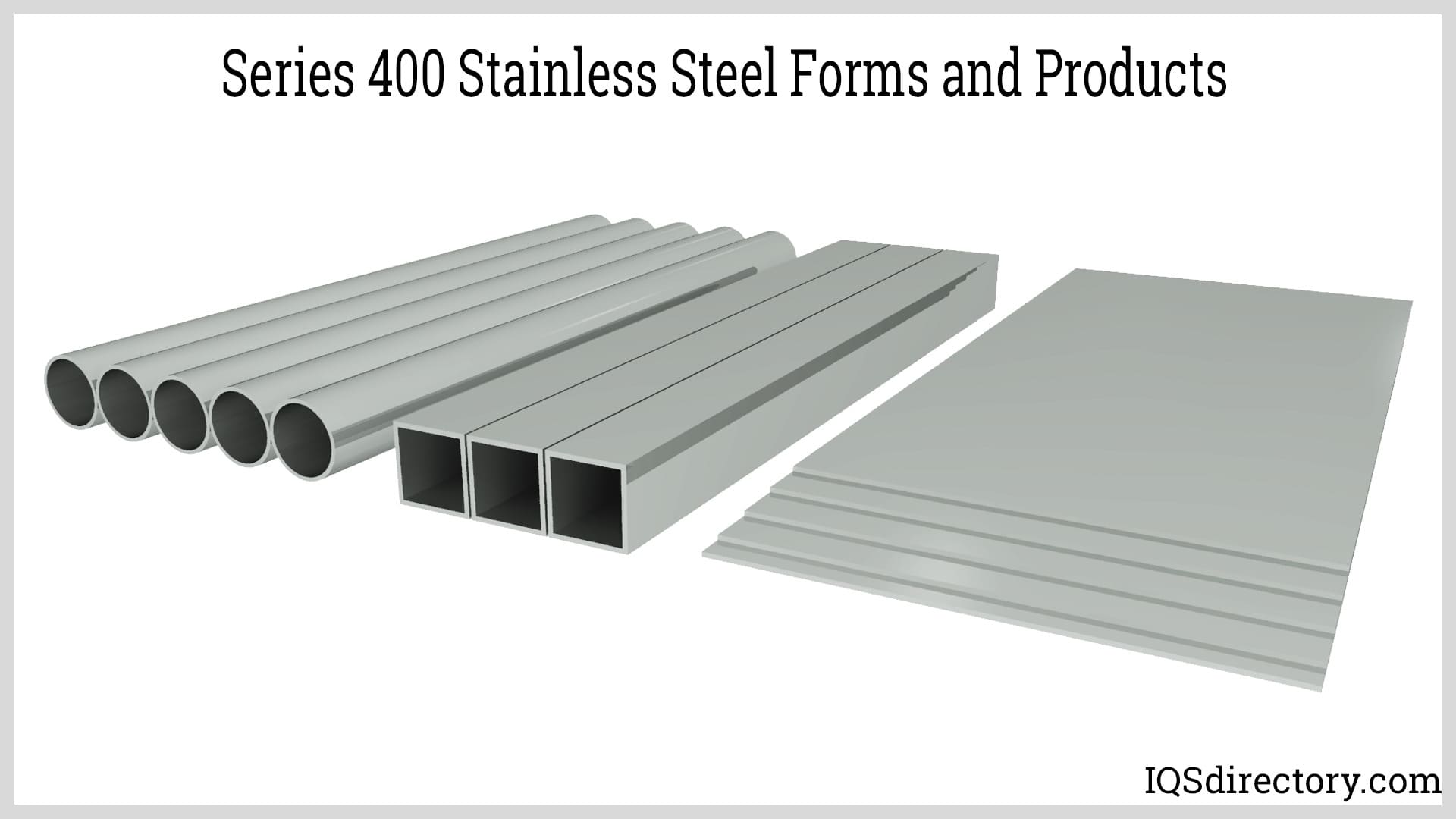

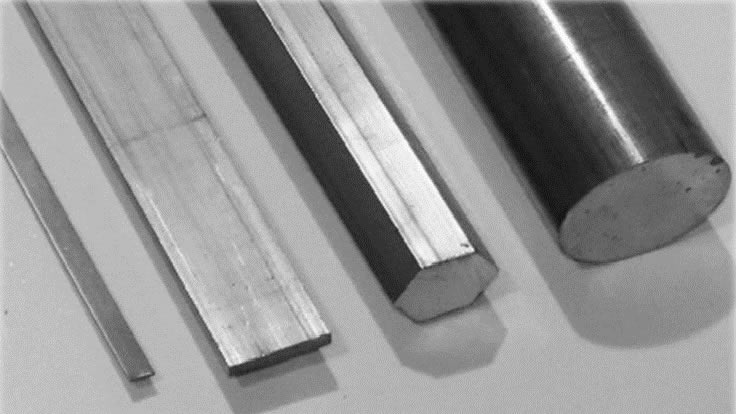

What are common forms available for 420 stainless steel?

420 stainless steel is available in a variety of forms, including bar, sheet, plate, rod, wire, and custom forgings to suit a wide range of industrial applications. Looking for a specific form factor? Browse supplier listings for custom offerings.

How does 420 stainless steel compare to carbon steel?

While carbon steel can achieve high hardness, it lacks the corrosion resistance offered by 420 stainless steel. For applications where both hardness and resistance to rust or staining are required, 420 is often the superior choice.

Conclusion: Is 420 Stainless Steel Right for Your Project?

420 stainless steel is a versatile, cost-effective solution for industries requiring a combination of hardness, wear resistance, and moderate corrosion protection. Its suitability for cutting tools, medical instruments, pump components, and industrial parts makes it a top choice for many manufacturers and engineers. However, if your application requires exposure to highly corrosive or marine environments, consider higher-alloyed grades such as 316 or 440C.

Ready to request a quote or compare suppliers? Start your supplier search to find the best match for your 420 stainless steel needs. For more information on stainless steel grades, machining tips, or sourcing strategies, explore our resource center or contact industry experts today.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services