We offer top-quality 410 / 420 / 430 stainless steel with a focus on quality, affordability, and convenience. Thanks to our multiple locations, we can deliver most orders within days, and have an extensive stock of all thicknesses in heat treatable grades. Contact us today to see how we can support your needs. We’re here to help you find the right solution! ISO 9001:2008 certified.

Cada Stainless is a distributor of stainless steel in strip, coil & sheet. All grades of stainless steel available- annealed, tempered in 301,302,304,316, straight and L grades, 17/4, 17/7, 420,430,440, temper rolling to specific thicknesses & tolerances available.

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

At Millennium Metals, LLC, we specialize in providing high-quality stainless steel products to meet the diverse needs of our customers across a wide range of industries. We take pride in offering an extensive inventory of stainless steel grades, shapes, and sizes, ensuring our clients have access to the materials they need, exactly when they need them.

At Alliant Metals, we dedicate ourselves to supplying high-quality stainless steel products and tailored services that meet the demands of a wide range of industries. As specialists in stainless steel, we work closely with our customers to deliver material that aligns with their exact specifications, whether the need is for standard stock or custom-cut solutions.

More 400 Stainless Steel Manufacturers

The rugged toughness of series 400 stainless steel grades makes them ideal for producing cutting tools with sharp edges. The hardness of series 400 makes it less malleable than series 300 stainless steels, another factor that makes series 400 the best choice for sharp tools.

The martensitic crystalline structure of series 400 stainless steel is a major reason for its hardness and resistance to wear. The versatility of series 400 has increased its use from manufacture of nuts and bolts to the production of surgical instruments and culinary utensils.

Although series 400 stainless steels are less resistant to corrosion than 300 series stainless steels, they are more popular for applications that require strength and resistance to corrosion. The low cost of series 400 is due to the alloys to produce series 400 stainless steel having been replaced with less expensive alloys that are used to produce other forms of stainless steel.

Two prominent grades of series 400 stainless steel are stainless steel 410 and stainless steel 416, which are popular due to their unique characteristics. Stainless steel grade 410 is a general-purpose stainless steel that can be hardened to produce a wide range of mechanical properties. Stainless grade 416 is the only free machining steel with an 85% machining rating.

Types of Stainless Steel Grade 410

Stainless steel grade 410 is used to manufacture tools and components that experience high stress. It has a chromium content of 11.5%, which gives it its limited corrosion resistance as well as resistance to certain mild chemicals. The corrosion resistance of grade 410 is enhanced with hardening, tempering, and polishing. Unlike grade 416, grade 410 can be easily welded using normal methods and preheating the metal to prevent cracking.

Stainless Steel Grade 410S

Stainless steel 410S has a slightly higher chromium content than grade 410 at 12% and has properties that prevent austenite formations at higher temperatures. Grade 410S is a low carbon version of grade 410, which makes it softer and more ductile when it is cooled rapidly. Since 410S has non-hardening characteristics, it does not require special treatments if it is exposed to high temperatures or being welded. When grade 410S is annealed, it becomes ferritic with corrosion resistance that is similar to 410 and oxidation resistance.

Stainless Steel Grade 410HT

Stainless steel grade 410HT is a heat-treated version of grade 410. It has the same chromium content as grade 410. The factor that differentiates grade 410HT from grade 410 is its heat treatment. As with grade 410, components made from grade 410HT must be preheated before being welded to avoid cracking. After welding, annealing is necessary.

Types of Stainless Steel Grade 416

Stainless steel grade 416 is the only stainless steel or steel that is free machining, which refers to the small chips that occur during the machining process. It has the highest machinability of any stainless steel. Machinability is expressed as a percentage with carbon steel setting the standard at 100%. Stainless steels have machinabilities that range between 40% and 80%. By comparison, grade 416 stainless steel has a machinability rating of 85%.

Grade 416 has a chromium content of 13% and gets harder and more corrosion-resistant when it is heat treated. It has a high sulfur content, which is one of the reasons for its machinability, a factor that makes it unsuitable for use in marine applications and high chlorine environments. It resists scaling during intermittent exposure to high temperatures over 760° C (1400° F) but can operate continuously in temperatures over 675° C (1200° F). Grade 416 does not weld well and requires the use of grade 410 using hydrogen electrodes and preheating.

Stainless Steel Grade 416HT

Stainless steel grade 416HT is a heat-treated version of grade 416 that has high machinability and magnetic properties with low surface friction. It has a low resistance to corrosion but has high strength and hardness. Its low friction and magnetic properties make grade 416HT less susceptible to seizing and galling. As with grade 416, grade 416HT has poor weldability, except when using grade 410 and hydrogen electrodes.

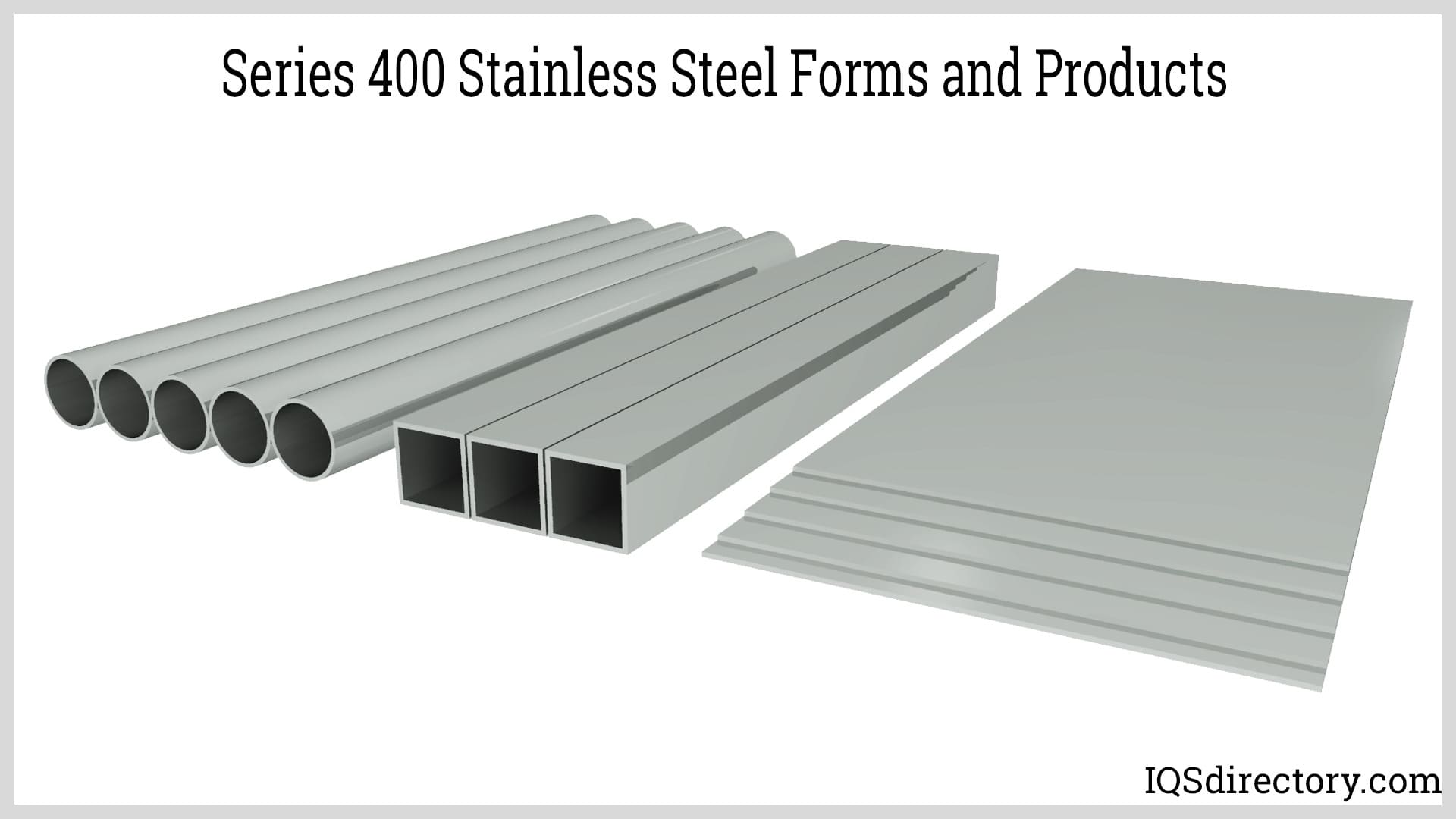

Forms of Stainless Steel Series 400

The delivery of stainless steel 400 to manufacturers takes several forms, which are designed to meet the specifications of the products to be shaped from stainless steel series 400 metals. During the production of stainless steel series 400, the combined metal alloys go through several steps to form a molten mass that can be shaped and configured into different forms.

Plates

With stainless steel plates, the molten metal is forced through a set of rollers that apply pressure to the molten pass and flatten it. The form of stainless steel plates is similar to that of stainless steel sheets, with the difference between the two being the greater thickness of plates that have a thickness that is greater than 2 mm (0.079 in). The thickness and shape of plates make them ideal for various machining operations.

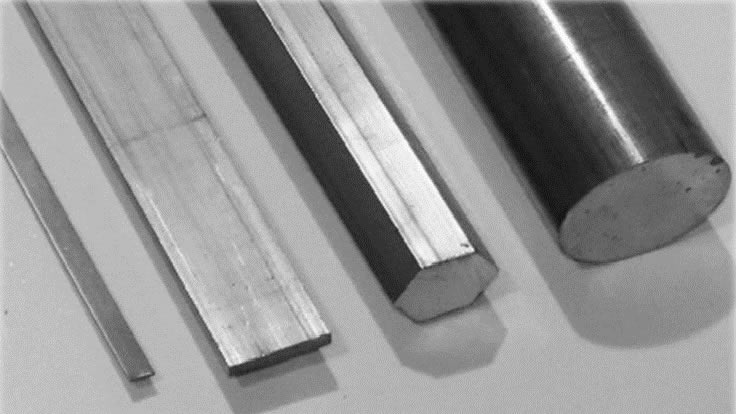

Rods

A very common form of stainless steel is rods, which are easy to transport and store. They come in different diameters and lengths. The shape of stainless steel rods makes them ideal for CNC machining and the production of fasteners. Depending on the type of stainless steel, rods are also used for architectural supports.

Bars

Bars are another common form of stainless steel that comes in a variety of shapes and sizes to meet manufacturing requirements. The types of shapes of bars include round, hexagonal, strips, and specialized forms for specific production requirements. To achieve a specific hardness rating, bars are hot or cold rolled to achieve intricate and complex cross-sectional shapes.

Sheets

Sheets of stainless steel are lighter than the other delivery forms. The size of sheets determines how easy they are to handle with most sheets being a few feet wide and twice as long. Sheets are one of the easiest forms of stainless steel for machining since they can be formed using a wide range of methods due to how thin they are. Sheets are deformed using various techniques including laser cutting and stamping.

Billets and Ingots

One of the oldest forms of stainless steel that is used for manufacturing are billets and ingots that are easy to ship and adaptable to several machining processes. Although they have an appearance that is similar to bars, billets, and ingots have a more compact and standard design that is easy to handle. In many cases, they are used for casting and molding since their shape makes it easy to feed them into a furnace.

Conclusion

Series 400 stainless steel grades are one of the most widely used forms of stainless steel due to their strength, toughness, durability, and minimal resistance to corrosion and chemicals. The grades of series 400 are less expensive than other forms of stainless steel, which makes them ideal for use in applications where cost is a factor.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services